Stanislaus Regional Water Authority Water Treatment Project

Stanislaus County, California

This project is led by the Stanislaus Regional Water Authority (SRWA), which currently consists of the cities of Ceres and Turlock. The project will require water release from Don Pedro Reservoir located about 25 miles up the Tuolumne River. Water will then be diverted from an existing infiltration gallery in the Tuolumne River located immediately downstream of Geer Road. Turlock Irrigation District (TID) will then redirect the water to a new water treatment facility just south of Aldrich Road for treatment and distribution to two terminal tank sites (one in Ceres and one in Turlock). Finally, the water will be distributed to the Cities of Ceres and Turlock for municipal and industrial uses.

CAInc prepared a Draft Preliminary Geologic/Geotechnical Study Memorandum for use in preparation of a Feasibility Study. The geologic setting, subsurface data, groundwater, and site seismicity/fault rupture were studied based on existing documents and reports of the area. Preliminary conclusions were provided for the Water Treatment Facility, Open Cut Pipeline, Trenchless Pipeline, and Terminal Tanks. Recommendations for Excavation/Stability, Groundwater/Dewatering, Liquefaction & Seismic Settlement, and Corrosivity were provided.

Humboldt Bay Municipal Water District Water Transmission Pipeline Replacement under Mad River

Humboldt County, California

The project will replace an existing 14” ductile iron pipe where it presently crosses the Mad River attached to a 1930’s era North Coast Railroad Authority (NCRA) steel-truss bridge. The bridge is vulnerable to damage or failure during an earthquake or severe flood. The pipeline is the main water supply to the communities of Blue Lake, Fieldbrook and Glendale. Total length of the river crossing is about 540 feet.

CAInc prepared a Preliminary Geotechnical Report for Phase 1 of the project, which provided preliminary (Phase-1) geotechnical assessment for a proposed new aerial pipeline crossing and includes an initial assessment for a horizontal directional drilling (HDD) alternative. Four test borings were completed, two on each side of the Mad River, along with geologic reconnaissance and preliminary laboratory testing. Alternatives included a new aerial crossing with suspension towers located on each bank, or installed under the river by horizontal directional drilling (HDD) methods.

Based on the preliminary report, it was determined that horizontal directional drilling (HDD) would be a feasible and cost-efficient construction method pending verification of the subsurface conditions and hydrofracture risk. For Phase 2, CAInc prepared a Final Geotechnical Report which included project coordination and preparation; geologic reconnaissance; subsurface exploration; geophysical surveys; and laboratory testing. Recommended the HDD pipeline be maintained within the bedrock unit as shown on Figure 5 to reduce the potential for frack-out.

Yuba County Water District – Well 17 Project

Marysville, California

CAInc prepared a Geotechnical Report for the proposed project. Foundation recommendations for the structures at each site include the following: Well 17 Site:

- Below ground sump station and mist eliminator structure supported on a concrete mat foundation 10 to 15 feet below existing grade

- Chemical & electrical control facility supported on an at-grade concrete mat foundation

- 25-foot diameter steel backwash tank supported on a shallow perimeter ring foundation with crushed rock or aggregate base belly support

- Ancillary structures/tanks including brine and fuel tanks, generator, pressurized filters, and transformer supported on shallow spread footings or concrete mat foundations

Storage Tank Site:

- Approximately 1-million-gallon, 100-foot diameter steel storage tank supported on shallow perimeter ring foundations, interior column spread footings, and crushed rock or aggregate base belly support

- Booster pump station supported on a 10 to 15 ft deep concrete basin/vault. Booster pump ancillary piping and equipment will be supported adjacent to the booster pump station on shallow spread foundations and concrete slab on grade

The project will also include approximate 1,000 linear feet of open cut water pipeline connecting the Well 17 and Storage Tank Site. To prepare the report, CAInc drilled, logged and sampled 8 borings at the sites and performed laboratory tests on the soil samples. Key Geotechnical considerations for the project include the presences of clayey soils that can make achieving proper compaction difficult during construction. CAInc used SETTLE 3D Version 3.0 software to evaluate immediate and consolidation settlement for both the storage basin tank and pump station. Grading, pavement, and utility trench recommendations were also provided.

Brentwood Waste Water Treatment Plant Pond #6 Improvements and Non-Potable Water Storage Tank and Pump Station

Contra Costa County, CA

In 2013, CAInc prepared a Geotechnical Report for the proposed deepening and liner construction at existing Pond #6 and a new pump station at the Brentwood wastewater treatment plant (WWTP). The purpose of the project is to deepen the pond and install a synthetic liner to prevent infiltration. The goal is to increase pond capacity while maintaining sufficient separation from groundwater to prevent potential blow-out or deformation of the liner due to hydraulic pressures. The liner will be anchored at the top of the slope according to manufactures’ requirements. A new pump station will be located near the northwest corner of Pond #6 and include a wet-well extending beneath the pond bottom. New piping will connect the pump station to the existing treatment plant.

To prepare the geotechnical report, CAInc reviewed existing geotechnical and groundwater data; excavated six test pits within and around existing Pond #6 and one test pit at the proposed pump station location; conducted laboratory grain size analysis on representative bulk samples; and performed geotechnical engineering analysis. The site was determined to be stable and suitable for the proposed pond improvements and construction of the pump station.

In 2015, prepared a Geotechnical Report for a new Non-Potable Water Storage Tank and Pump Station project at the wastewater treatment plant in Brentwood. The 3-million-gallon prestressed concrete storage tank is about 25 feet in height and 170 feet in diameter. The tank is used to store non-potable water (NPW) for the NPW distribution system. The storage tank was constructed partially below existing grade and supported on a perimeter ring foundation, interior column footings, and concrete slab on grade floor.

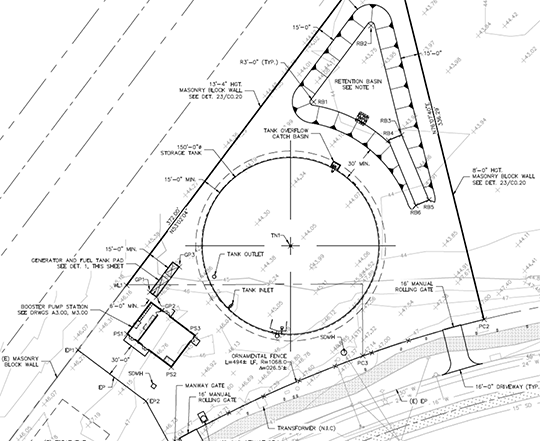

Atherton Tank and Pump Station

Manteca, San Joaquin County, CA

Ben Crawford and the CAInc team prepared geotechnical recommendations for the Atherton Tank and Pump Station (formally Manteca Well 26 and Booster Pump Station). The project consisted of three new booster pumps and a 90-foot diameter steel water storage tank. Performed detailed settlement calculations and determined that an over excavation and recompaction of the near surface loose sands would be required. Provided foundation recommendations for a reinforced concrete mat foundation and perimeter ring foundation.

In 2013, the City of Manteca upgraded the project to include a 150 ft. diameter, 33 ft. tall, 3.6-million-gallon steel water tank founded on a perimeter ring foundation; a dedicated booster pump station, piping and standby on-site electrical generation. The project has been completed utilizing design/build delivery. CAInc completed the design/build process and worked with the City, Design Team and Contractor to update our recommendations during construction.

Project Elements

- 150 ft. diameter, 33 ft. tall, 3.6-million-gallon steel water tank. The tank walls will be founded on a perimeter ring foundation. The belly of the tank will be supported on a compacted layer of non-corrosive material.

- Booster pump building supported on shallow spread footings with concrete slab-on-grade floor to house below ground booster pumps with individual pump cans installed to approximately 10 ft. below finished grade.

- Generator and fuel tank supported on shallow mat foundation.

- Paved driveway.

- 175,000-gallon retention basin.

- 8 to 13 ft tall masonry block walls located along the east and south property lines.

Willow Creek Wastewater Treatment System

Humboldt County, CA

Crawford & Associates prepared a Geotechnical Report to provide geotechnical recommendations for the proposed wastewater treatment system, which will replace the aging individual septic systems with a single community wastewater collection and treatment system. The collection system includes 103 connections throughout the town – both commercial and residential. The collection system will use 6-inch gravity pipelines installed within existing roadway easements throughout the town. To prepare this report, CAInc reviewed available geologic maps of the site; conducted a site review; drilled, logged and sampled exploratory borings; performed laboratory tests on representative soil samples from the exploratory borings; and performed geotechnical engineering calculations and analysis to develop recommendations. Provided recommendations for the collection system, pressure main, septic and recirculation tank foundations, and filter bed wall foundations.

Geotechnical Concerns

- The presence and quality of bedrock within the depths of pipe inverts

- Potential for encountering wood debris and other buried features at the treatment plant associated with old mill operations

- Seasonally-perched groundwater within shallow sediments overlying the rock

- Unmarked underground structures in the collection system area

City of Modesto Industrial Tank No. 13 and Pump Station

Modesto, Stanislaus County, CA

In 2010, Ben Crawford and David Castro, while working at Blackburn Consulting, completed a Geotechnical Report for the City of Modesto Industrial Tank and Pump Station. The report contained surface and subsurface condition descriptions, geotechnical design, and construction recommendations for the proposed 4-million-gallon concrete tank, 12-million-gallon per day pump station, CMU block structure, and 1-million-gallon retention basin.

Currently, Crawford & Associates, Inc (CAInc) is providing the required grading observation and compaction testing, and periodic concrete, masonry, steel, and welding special inspection. CAInc is also performing laboratory testing on sampled materials, and preparing and providing a daily field reports with findings, a description of the daily events, test results, and providing Geotechnical consulting services during construction.

North Valley Regional Recycled Water Program

Stanislaus County, California

The City of Modesto currently discharges treated wastewater into the San Joaquin River. Once constructed, this project will primarily discharge into the Delta-Mendota Canal (DMC) where water can be reclaimed primarily for agricultural purposes downstream.

Key project components include:

- Improvements to the existing wastewater effluent pump station

- Trenchless pipeline installation beneath the San Joaquin River and Patterson Irrigation District canals

- About 32,000 linear feet of 42-in diameter pipeline constructed about 7 to 8 feet bgs primarily within county roadway easements between the San Joaquin River and the DMC

- A terminal outfall structure to control reclaimed water from the pipeline to the DMC

- A meter vault to measure flow

- A variety of ancillary structures, including manholes, blowoff assemblies, air valve assemblies, and isolation valves

CAInc prepared a Geotechnical Data Report which provides information on subsurface conditions; groundwater; results of lab and corrosion testing; and seismic data.

CAInc also prepared a Geotechnical Report for proposed structure (Pump Station Modifications and Delta Mendota Canal Overflow Structure) and the pipe improvements. Pipeline recommendations were provided, including calculating the Composite Modulus of Soil Reaction (CMSR), thrust restraint for large diameter pipelines, trenching, and trench backfill requirements. Other recommendations included mat foundations for the outfall structure and meter vault, grading recommendations for temporary construction slopes, and fill placement and compaction.